Inspur NE3412M5 Power Consumption

Our Inspur test server, we hooked this system up to our lab power meters and took a few power readings at 120V using our Extech 380803 True RMS power analyzers.

- Idle: 65W

- STH 70% Load: 91W

- 100% CPU Load: 132W

- Maximum Recorded: 451W

As one would imagine, there is a lot of configurability here with CPUs, GPUs, memory, and storage. We see these more as directional guidelines in our configuration.

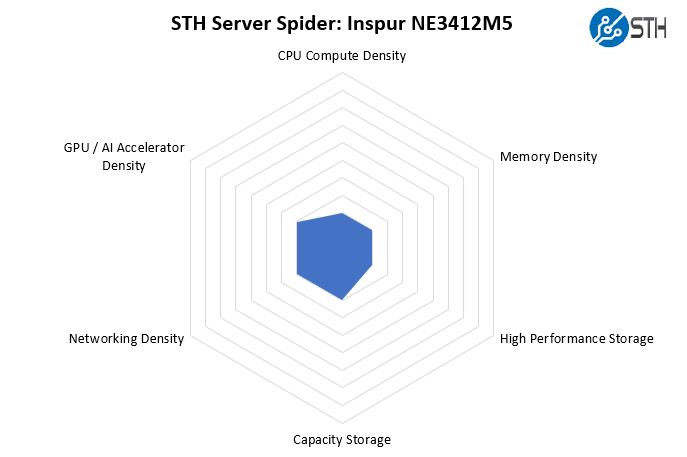

STH Server Spider: Inspur NE3412M5

In the second half of 2018, we introduced the STH Server Spider as a quick reference to where a server system’s aptitude lies. Our goal is to start giving a quick visual depiction of the types of parameters that a server is targeted at.

Our STH Server Spider generally measures density, but density is not the point of the NE3412M5. Instead, this system is about being mobile and being able to handle the stresses of being shipped across distances.

Final Words

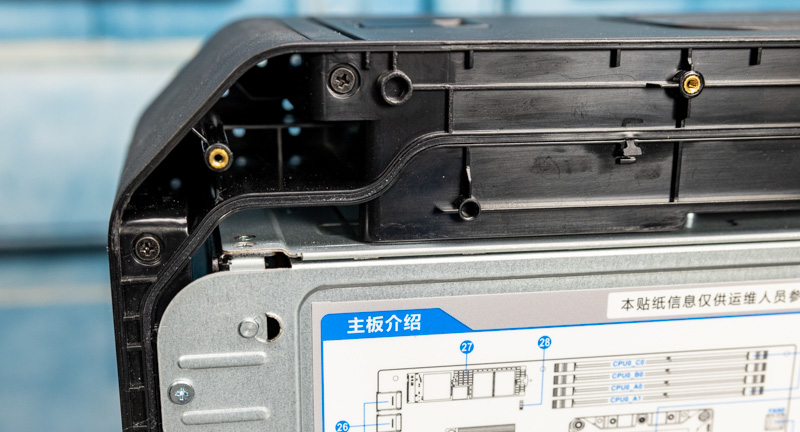

Overall, this is a very interesting system. Sometimes we see systems on the market that are marketed as portable but that are more of systems that simply add a handle to them. The Inspur NE3412M5 is much better designed than those systems. There are features such as the handle compartment to store cables that are differentiating. Other features such as the multiple layers of plastic, gaskets, and metal areas for protection during shipping are extremely useful as well.

The key point for our readers is that this is a system that was designed for hyper-scalers to provide an edge compute (CPU and GPU) offering with local storage to cloud customers. Inspur often engages in co-design with its large customers and this is an example of where it appears as though those design cycles have led to some major design directions.

The above photo is a very good example of this. One can see the gaskets, as well as just the thickness of the hard plastic covering that, encases the metal structures of the server and the valuable components. We did not try this, but this feels like a server that can survive a 1-2m drop onto a concrete floor unscathed.

One item we wish that the server had was easily replaceable external air filters. Some edge environments are very dusty so those would have been nice to see. This system is designed more for rugged shipping but indoor and in-vehicle operation so that may be the reason behind that design direction.

Overall the NE3412M5 is an impressive edge comptue platform that is designed to survive transportation to remote locations and provide a local outpost for compute capabilities.

You didn’t mention weight, but it looks heavy.

Man this is cool. I wish you’d have done a video to see those doors open in action

Interesting approach to a specific market segment.

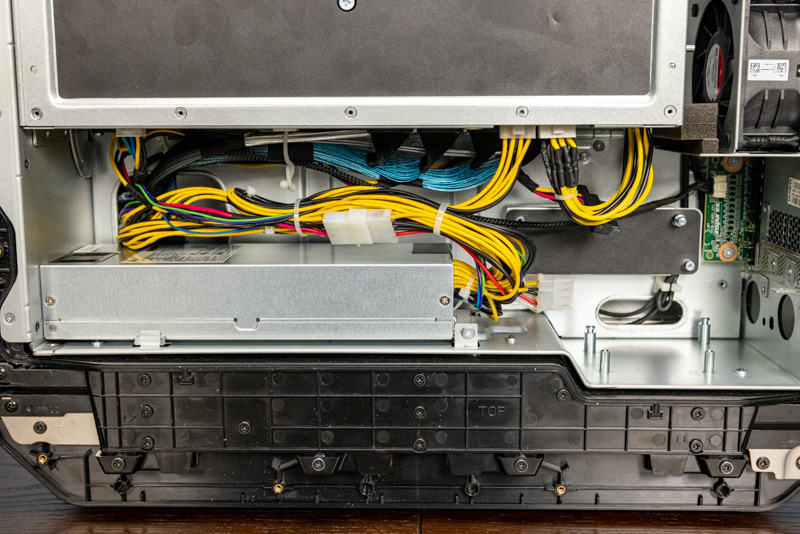

The interior views were “off putting” to me. Can you say “cramped”? I knew you could.

Long-run data covering interior case thermals would be interesting to see. All the durability in the world means nothing if the hardware slowly roasts itself.

Note to all HW manufacturers: Leave the roasting and smoking to a qualified chef in a proper kitchen.

Also curious to not see a label that says, “No user serviceable parts inside”, but then again the case labels are not in English, perhaps for good reasons.

This is a small form and looks more “efficient” than “cramped”.

to sleepy and awake – either here or in the vast majority of cases and server internals the recent lenovo DIMM fan shrouds notable for rarity — now we’re entering a fast paced generational upgrade sequence, I’m starting to think it’s lazy and can’t understand why the engineering isn’t of sufficient economic value to manufacturers when I think my company would tolerate a 5 percent price hike just to get given useful numbers about thermal characteristics

there’s no obvious thermal circulation design here or anywhere and I think that’s just poor in this age

to awake

this is why modular encapsulated subsystems on the CXL busses of the near future are where I hope we’re going. VME bus… hmm!

I really hope you do a video on this, I am really enjoying your movies on Youtube.