Key Lessons Learned

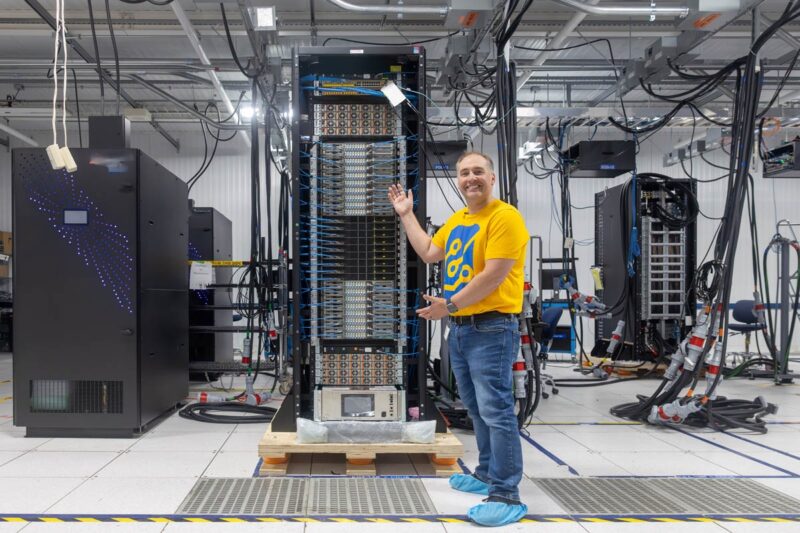

The scale of this facility is truly impressive. While I do not want to give exact numbers of Dell IR7000 racks we saw, folks can fairly easily count $100M worth of racks being built in our photos and footage. This was also during a relative down period that allowed us to come in and film where it was not going to be as disruptive to the manufacturing process. It should be abundantly clear from the video that this facility is designed to handle billions of dollars of in-progress AI infrastructure build-out. As a sense of scale, in the video, I mentioned that walking across one of the two manufacturing floors at a pace fast enough that my watch asked if I wanted to record a brisk outdoor walk, it still took almost two minutes to walk end-to-end.

Taking this into context, that means companies who want to play in the AI space need global manufacturing that is capable of handling that type of build activity even between major builds. The requirements may also be for specific country or region manufacturing. Dell has dozens of factories in its global network and several in the US. Franklin, as we showed, is focused on the higher-end AI build-out in the US.

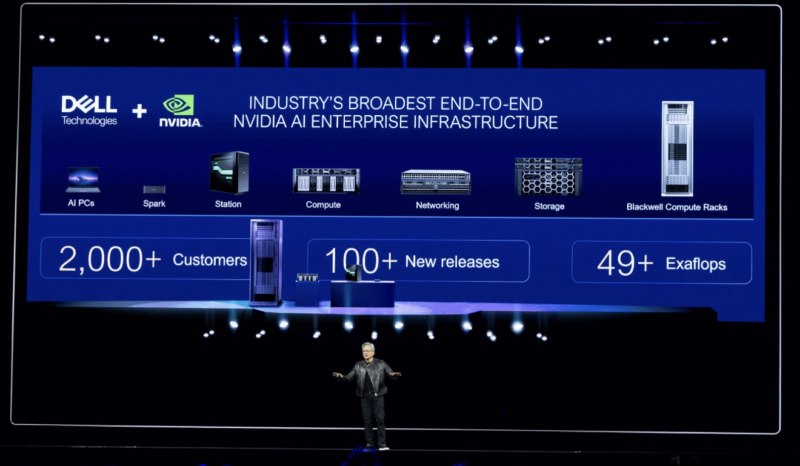

Dell has signaled that it is not just focused on the high end, but also a wide array of AI compute solutions from notebooks and edge devices all the way up to the Dell Integrated Rack Scale Solutions we saw here.

Final Words

The Dell Technologies manufacturing facility in Franklin, MA is enormous and helps give Dell a manufacturing footprint in the US for its high-end AI systems. That alone is a key differentiator.

The facility is designed to handle large volumes of racks, both liquid-cooled and air-cooled, to service a variety of customer applications. To be clear, even in the photos and walking around you can see how Dell is making tweaks to its AI systems due to customer demands. That is something truly underappreciated in the industry, but you can see it here.

Building racks that in their current generation are 120-140kW and in two years are expected to be in the 600kW per rack range before heading into 1MW per rack, is not easy. Facilities need to be designed to quickly process large volumes of AI systems so that they can be deployed with speed.

Something that you appreciate being in the facility is that in building these systems, a lot has to go right. These are high-end complex assemblies that need to operate flawlessly in a customer data center. With so many components and so much hardware and software being packed into these racks, just being able to manufacture these is on a completely different level than building standard servers. Some skills and lessons may be shared, but I certainly got the sense that the reason Dell is building its AI servers in Franklin is because this is a facility accustomed to building mission-critical storage arrays and converged systems. Each of these systems needs to leave the factory being as reliable as possible because they are then installed and operated in clusters at a much larger scale than many traditional servers.

This is a facility that has been building systems for decades, but this is a first look at what is going on inside the factory walls. It is also an important factory for Dell, Dell’s customers and partners, and those in the broader AI industry. Hopefully, our STH readers enjoyed this one.

Thank Yous

I also wanted to extend a quick thank you to the Dell team in Franklin, and everyone that made this possible. Whenever we do these videos there is a lot of effort that goes into clearing space for us and removing elements that folks do not want to show on camera. The folks in Franklin were awesome about graciously hosting this tour in the middle of a production line.

Also a quick thank you to Michael Dell and Jeff Clarke for making this tour happen.

Hopefully, our STH readers and YouTube viewers enjoyed this tour. We have several others planned this year and after doing this tour we invested in making the next ones even better.

I’m loving your tours. I’m also appreciative that you’re doing the article not just the video

Also really enjoying these tours and the peek behind the curtain. Reminds me of types of journalism that tech sites used to do so well before consolidation hit and they became ad heavy, AI content mills.