Beelink announced four new items. It is offering replacement bottom covers for its GTR6, GTR7/ GTR7 Pro mini PCs. It is also taking user feedback on its driver update frequency and offering new drivers.

Beelink GTR7 and GTR6 Bottom Cover Replacement

Beelink’s new bottom covers help add more cooling to the bottom of the systems that house the RAM, SSDs, and WiFi cards. For those looking for cooler temps, especially those users who have been overclocking these platforms, adding a vented bottom cover allows for what the company says is a 3-4C improvement in temps versus just using the existing side vents.

The Beelink GTR6 was the company’s upgrade to the AMD Ryzen 9 6900HX. That brought more iGPU capabilities to the platform.

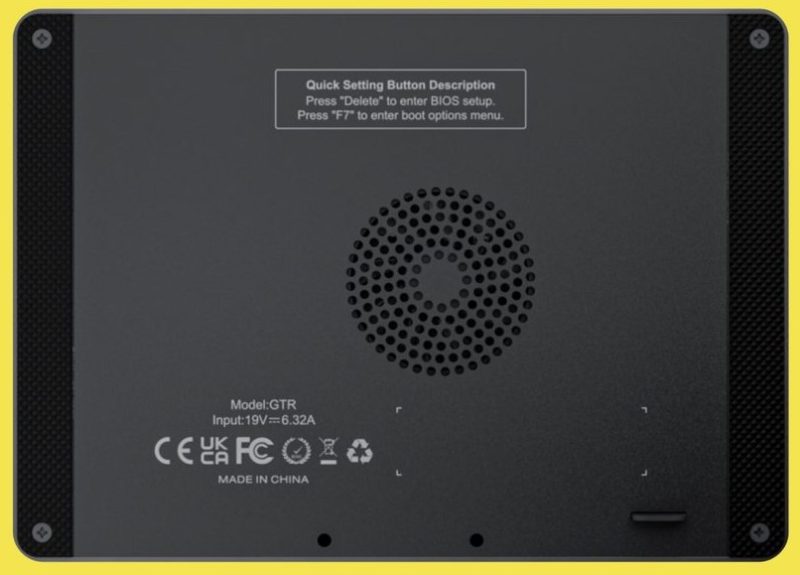

The bottom of the unit is what will have the optional replacement.

Here is what the new bottom cover looks like with the vent:

The Beelink GTR7 and GTR7 Pro are very similar units with the base model having an AMD Ryzen 7 7840HS and the Pro model with an upgraded AMD Ryzen 9 7940HS.

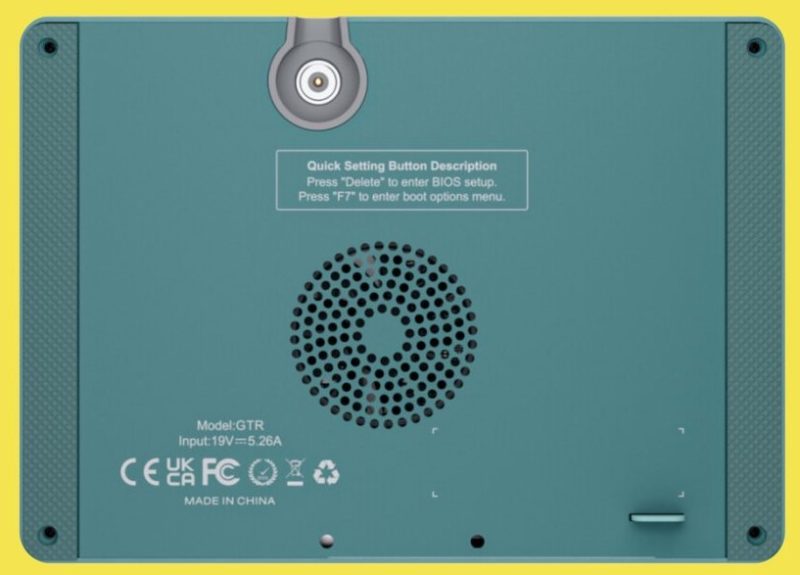

Here is the bottom panel of the GTR7.

Here is what the new bottom cover looks like with the vent.

Beelink says that it will send color-matched bottom panels for these parts.

Final Words

We have not had our GTR6 and GTR7 units throttle, but we also tend to only add low-power SSDs if we do add any to the systems and do not overclock memory. This is something we have been keenly watching since we saw severe throttling in our Minisforum UM690 Review. One of the biggest challenges in these mini PCs has become cooling as chip TDPs have increased and components around the chips have started to use more power as well.

Beyond just the vents, Beelink is acknowledging that it needs to provide better driver updates, and says we can expect new drivers on July 20, 2023.

Overall these are good changes since it shows that Beelink is getting the message that it needs to better support its systems. With Intel exiting the NUC business there is a sizable opportunity to capture a market, but that will require closing the support gap. Now the question is whether the replacement bottom covers will arrive in time for the GTR7 Pro review.

How about increasing the dimensions?

I don’t understand why this mini PC’s are so mini. They are too small and I’m pretty sure a lot of people don’t need such a small size and would rather have a better cooled mini PC than a small size.

please make a bigger mini PC’s without these problems

Alan, my guess is that these companies have been doing this form factor for awhile and the originals weren’t good for much more than general productivity, kiosks, light IT tasks etc. I had a couple of NUCs with 8th gen Core i3 and i5 CPUs and that was basically it. But then Intel switches to big.LITTLE, AMD goes from 7nm to 4nm in a year and both double the quality of their integrated graphics … Iris Xe can do 720p and RDNA 3 can do 1080p at 60fps. So now they are good for video editing, gaming, software design and a bunch of other stuff that the original minis weren’t.

Do a redesign? Costs money. Intel made their NUCs bigger but it was pointless … they cost as much as regular desktops, were almost as big but not as powerful. Beelink and the rest realize that cheaper and smaller are the whole point. There are plenty of better options for bigger and more expensive. You can get a mid-tower with a 12th gen Core i5/Ryzen 5 5600 CPU and Nvidia 3080 GPU for not a whole lot in a ton of places. So they are sticking with their original designs which is the right call.

Alan, they do have bigger mini PCs. MFF by Lenovo, Dell, HP are somewhat larger with socketed CPUs and are more robust. AsRock deskmini are a bit bigger, then come ITX of varying sizes. These small minis do have their audience who want minimal footprint for the back of the monitor or as HTPCs.

Thadec, Intel’s NUC’s aren’t bigger. They have +-the same size as these miniPC and I think this is the reason why companies like Beelink or Minis use such size. Intel set the miniPC size standard.

Intel have special bigger/gamers editions but classic NUC has the same size as these miniPC’s.

I think that a miniPC larger by one or two centimeters would not hurt this concept and would add space for mounting a larger and quieter fan, which would solve all their problems , and RAM/SSD coolers wouldn’t even be needed.

Redesign?

This bottom cover redesign cost nothing?

Adding one or two centimeters to the height and adding a standard/bigger fan wouldn’t cost much more. It would also solve possible future problems with cooling.

(this is the third time that I am writing this because it looks like that this page will automatically reload and then you will lose the comment that you’re writing)

@Alan

re: “I don’t understand why this mini PC’s are so mini. They are too small and I’m pretty sure a lot of people don’t need such a small size and would rather have a better cooled mini PC than a small size.”

Intel set this original size and it has sold well enough that it CONTINUED with this size for ~10 years.

The footprint of the GTR series has remained the same, so far, at 168 mm x 120 mm, but it is the height that has changed over the different, successive generations where it went from being 39 mm tall (GTR5) to 43 mm (GTR6) to 49 mm (GTR7/GTR7 Pro), which results in a volume of 0.786 L to 0.867 L to 0.988 L respectively.

So, it HAS gotten bigger over time.

But more to your point, there are a LOT of applications where you don’t NEED the full size (or even bigger) mini PC, afterall, the name of the game is LITERALLY in the name of the type of PC: *MINI* PC.

re: “Thadec, Intel’s NUC’s aren’t bigger. They have +-the same size as these miniPC and I think this is the reason why companies like Beelink or Minis use such size.”

That’s not exactly entirely true.

The 8th gen Intel NUC has a footprint of 117 mm x 112 mm and a height of 51 mm (0.668 L).

9th gen NUC Extreme (Ghost Canyon) = 238 mm x 216 mm x 96 mm = 4.935 L

10th gen: 117 mm x 112 mm x 38 mm (without 2.5″ SATA support) = 0.498 L

117 mm x 112 mm x 51 mm (with 2.5″ SATA support) = 0.668 L

11th gen Enthusiast NUC: 227 mm x 145 mm x 40 mm = ~1.3L

etc. etc. etc.

So, there are CLEARLY NUCs that ARE bigger than these mini PCs (just as there are also NUCs that has retained the original footprint of 117 mm x 112 mm).

re: “I think that a miniPC larger by one or two centimeters would not hurt this concept and would add space for mounting a larger and quieter fan, which would solve all their problems , and RAM/SSD coolers wouldn’t even be needed.”

That’s not true.

As Cliff already notes in this article (cf. Minisforum UM690), without more direct cooling for the faster DDR5 RAM and more performant NVMe SSDs, you CAN run into situations where the system WILL start to thermal throttle itself (similar to how the NUCs, at least with the “classic” (as you call it) footprint quite often. (At least that has been my experiences with Intel NUCs, both for the 7th gen and the 8th gen.)

So, no, having a larger chassis will not necessarily solve this issue without more direct cooling available to these components (which is dependent on the board layout).

re: “Redesign?

This bottom cover redesign cost nothing?

Adding one or two centimeters to the height and adding a standard/bigger fan wouldn’t cost much more. It would also solve possible future problems with cooling.”

Sure. If you ignore the $350k cost for the tooling change, absolutely.

What you’re probably thinking about might ONLY be the incremental material cost, but you’re completely neglecting or forgetting about (or just right ignoring) how much it would cost in tooling to implement this engineering change request/engineering change notification.

I don’t remember of the different generations of the chassis were made of plastic or metal, but if it is injection moulded plastic, making this change can EASILY be $150k, if not more.

And then you have to divide the cost of the incremental tooling change by the number of units that you think that you’re going to be able to sell, which, I haven’t seen any sales figures published by Beelink (nor Intel for their NUCs for that matter).

(I used to work in plastic injection moulding for my co-op job.)

And if the walls of the chassis were taller, now you have to worry more about shrinkage issues where the top part of the wall would “bow in” towards the middle, because of the height of the wall, etc. etc. etc.

If it were easy and simple, Intel would’ve done it to their NUCs a LONG, LONG time ago. (And if it bows in too much, now you have to add in stiffening ribs to the plastic, which means that now you are eating into the space of where the board goes, which means that you won’t be able to maintain the 117 x 112 mm footprint of the NUCs nor the 168 mm x 120 mm footprint of the Beelink GTR series.)

Run your moldflow simulation and look at your warpage results.

Every countermeasure that you want to deploy to fight against this costs you money, which will increase the cost of the part and therefore; your overall product.

What you thought was going to be pennies for the incremental material cost, now suddenly adds $4.50 USD per unit, on a part where they might argue about the 0.7 cents it costs for each extra screw that they have determined, they can minimise.

And it’s so easy for an incremental $4.50 USD per unit total cost to become an extra $100 USD for you, by the time you want to buy the product. For some, that can be the difference between being able to afford it vs. not or it can be the difference between whether the STH team would recommend it as a buy vs. not, at that extra $100 price point.

I have a GTR 7 Pro Ryzen 9 and I just bought some longer screws and a few jam nuts at eth local hardware store for just over $4 to fix this issue. They lift the bottom plate a few cm to provide better airflow. Larger cases are not the answer. There was nothing wrong with this form factor until I bought a much faster NVMe.

The driver issue can be assigned squarely to AMD. The chipset and video drivers aren’t due to be released now until the 26th. The drivers as shipped would have sufficed if the official AMD drivers weren’t delayed. I work for a school district that has 60 of the GTR5s and are purchasing over 100 of the GTR6s for our engineering, digital art and animation labs. They have performed flawlessly doing CAD, engineering apps, photoshop, and Maya

At the risk of sounding like a commercial, (no I don’t get anything from them) Our support has been very good, especially when you compare it to Minisforum. Also, the physical quality and tight tolerances of manufacture are quite impressive. I am a former machine designer and have seen some really badly made computers in my time.

How can i get the new bottom panel? Where would I find that link for that part?

Churchill July 24, 2023 At 3:42 pm wrote,

“How can i get the new bottom panel? Where would I find that link for that part?”

Exactly!

@Cliff Robinson, that information should have been provided before your writing was approved as fit for STH publishing. Can you please provide NOW? Thanks.

Churchill and iq100 – you can reach out to their support email at support-pc[at]bee-link[dot]com – they told me: “We have registered your information and will send it to you as soon as possible. After sending it out, we will notify you of the logistics tracking number.”

So not sure how long it’ll take or when to expect it. Hope that helps you guys out!

-Justin