Fabric8Labs did a presentation two years ago at Hot Chips that was awesome. Over the last two years, the company has been expanding its playbook of offerings and the problems it solves. In this talk, it also delves a bit more into how additive manufacturing is utilized. You will not believe how this works.

We are covering this live, so please excuse typos.

Fabric8Labs ECAM Enabled Thermal Solutions at Hot Chips 2025

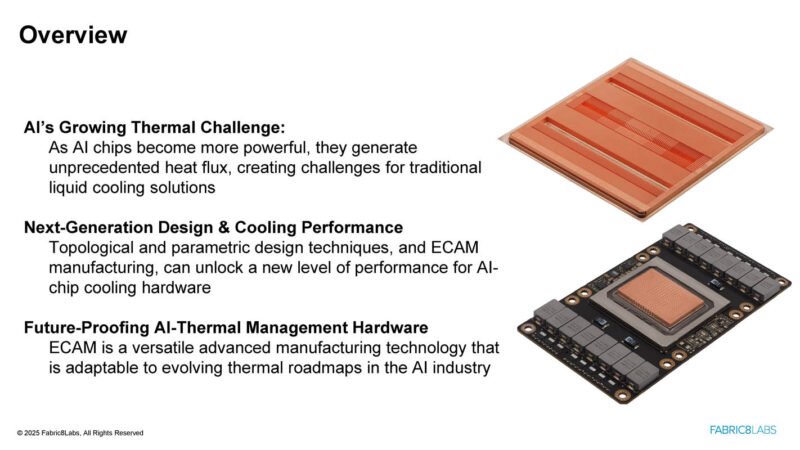

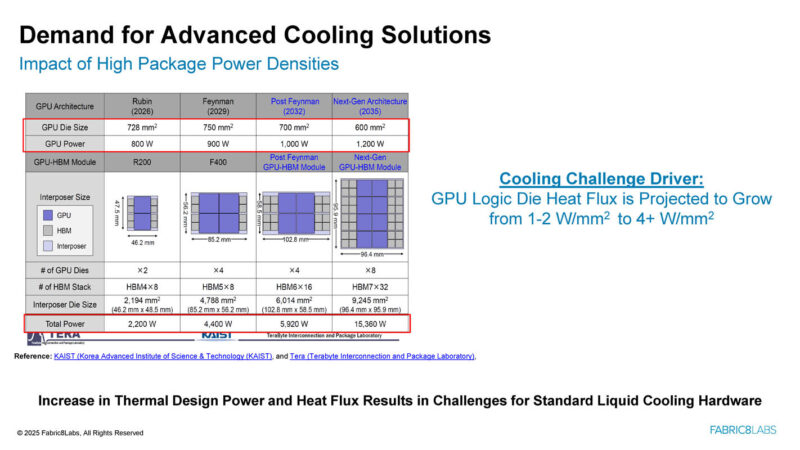

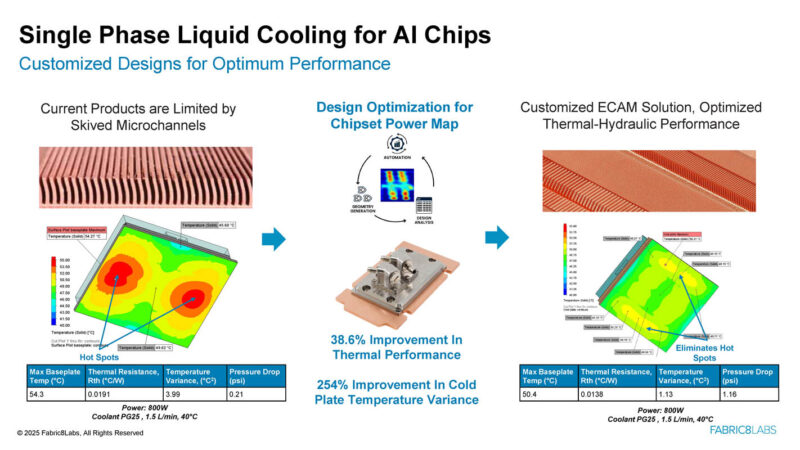

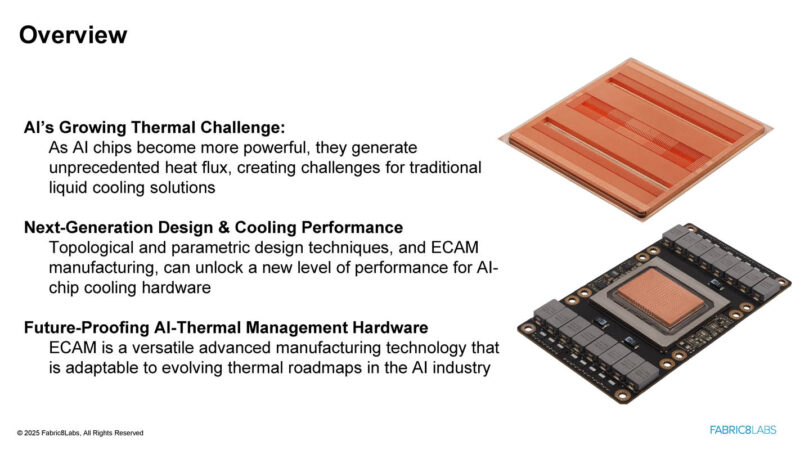

Something is happening in the industry. AI chips are now composed of chiplets, with chiplets that have very different thermal profiles being packaged together. Also, chips are using more power. As a result, the thermal solutions need to get more complex, or at least more thoughtfully designed.

This is a look at future GPUs and the cooling required for them.

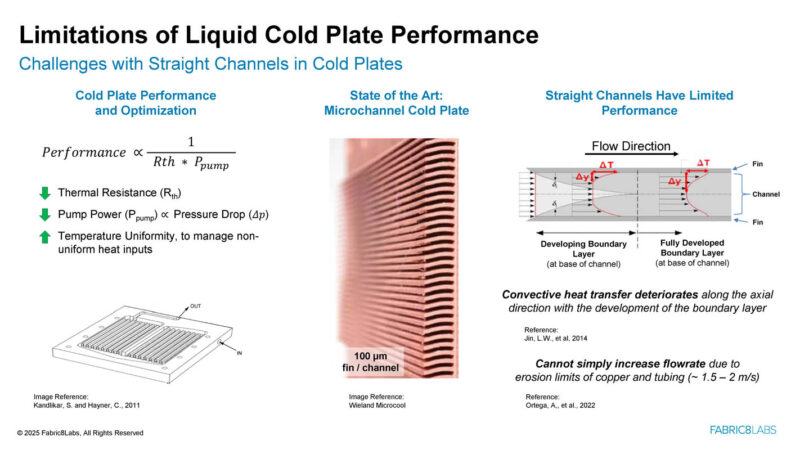

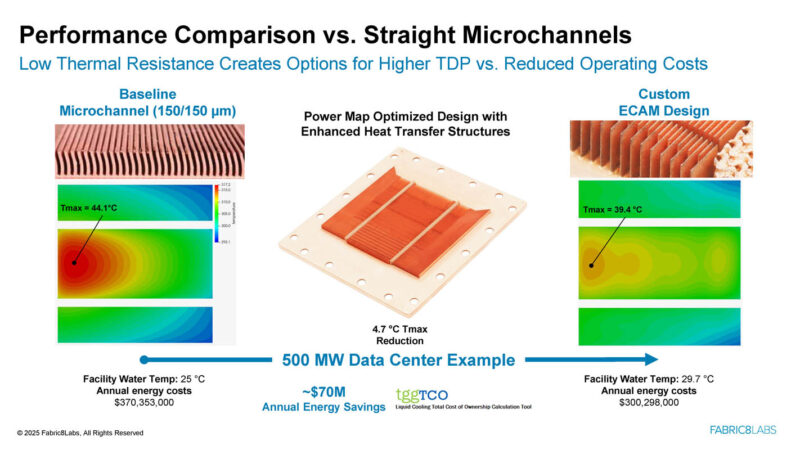

Most coldplates today have straight microchannels. Fluid flows down the channels and the additional surface area helps transfer heat to the fluid. This is made by skiving where a machine makes these fins out of a copper block.

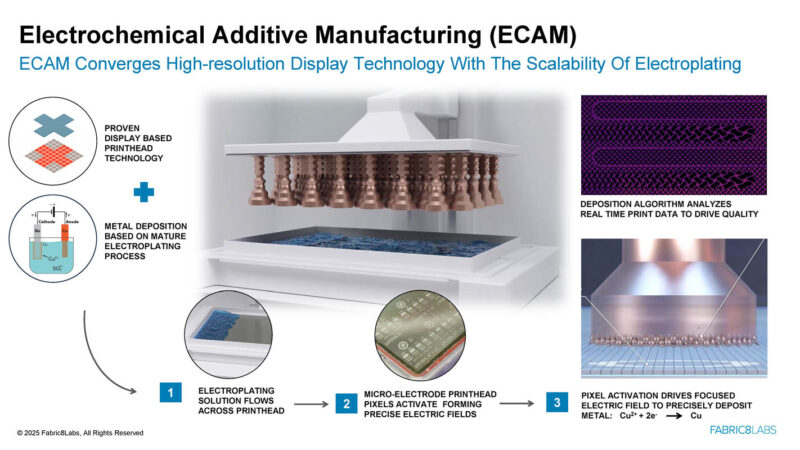

Ok, let us get crazy on how this Fabric8Labs works. They are essentially takeing an OLED display, and using the electrical charge instead of light to deposit copper at pixel resolution. This is electromechanical additive manufacturing or ECAM.

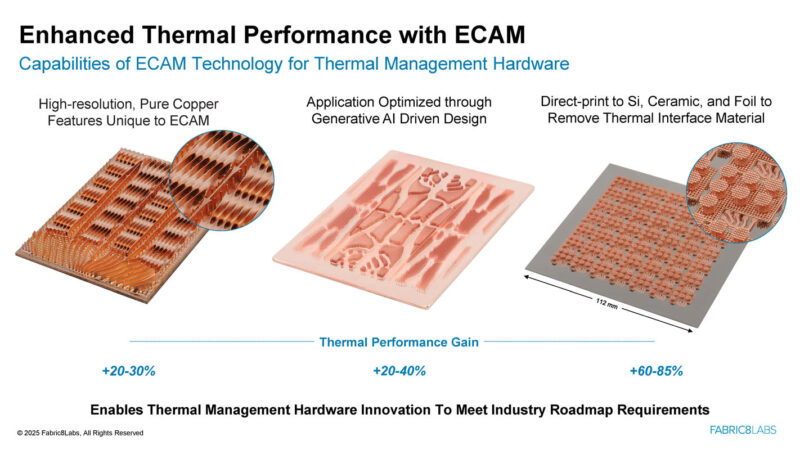

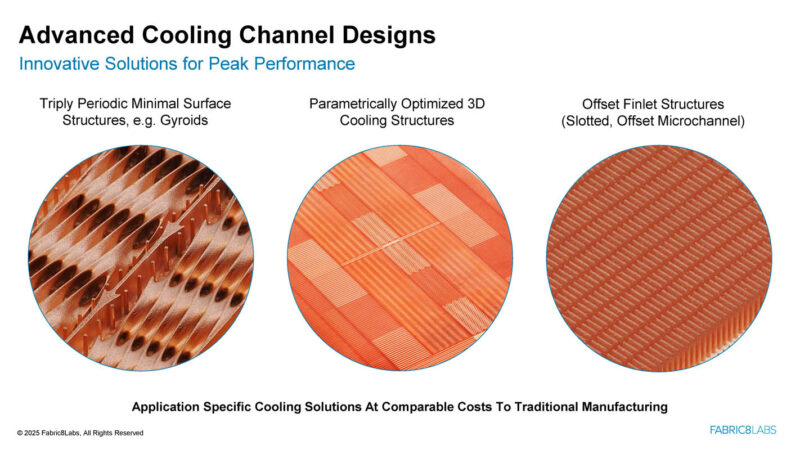

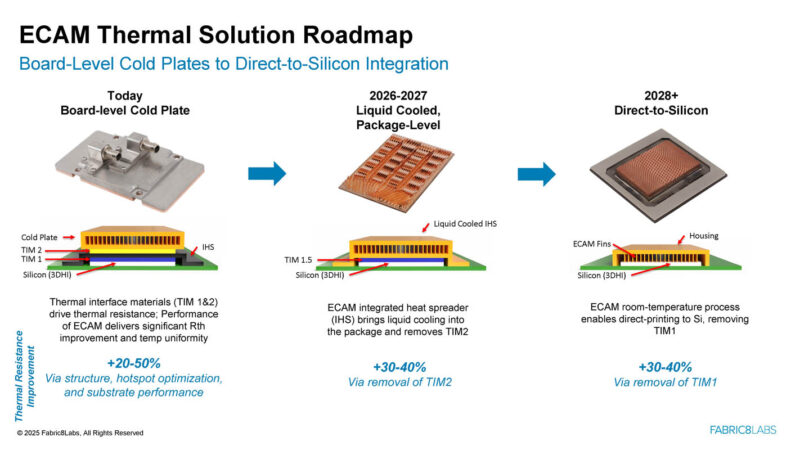

With that, you can make much more complex structures that a skiving machine cannot do. Previously, we showed what was in the first 20-30% gain photo where the 3D structure was optimized to make a better coldplate. The next is an AI driven design where it is optimized for a given chip and application. Finally, there is the future case where the copper is deposited directly on the silicon so that the cooling is directly on the heat source.

One of the challenges in these microchannels is that if a microchannel gets clogged it creates a failure point for the system. Being able to make designs like the offset finlet structures allow for a blockage to not plug the entire channel.

Here there is a split flow design to cool the two hot spots on the chip.

Doing this extra work means that you get better performance because the flows can be better optimized.

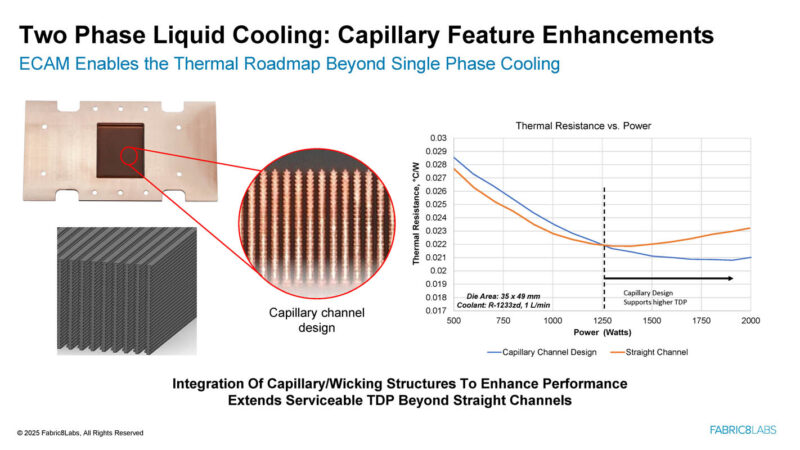

At some point, single phase liquid cooling will not be sufficient. The Fabric8Labs technology can make things like the capillary design that helps make even pumped two phase liquid cooling more efficient.

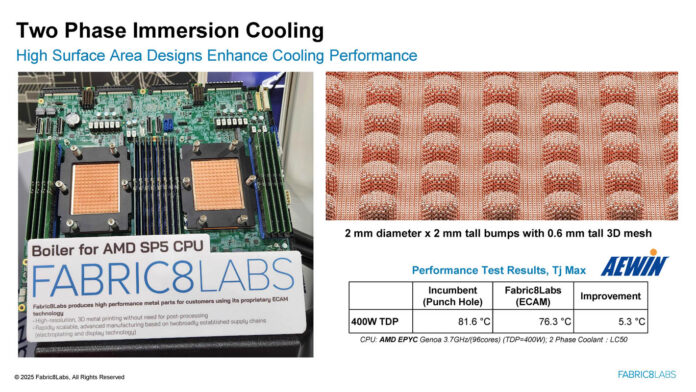

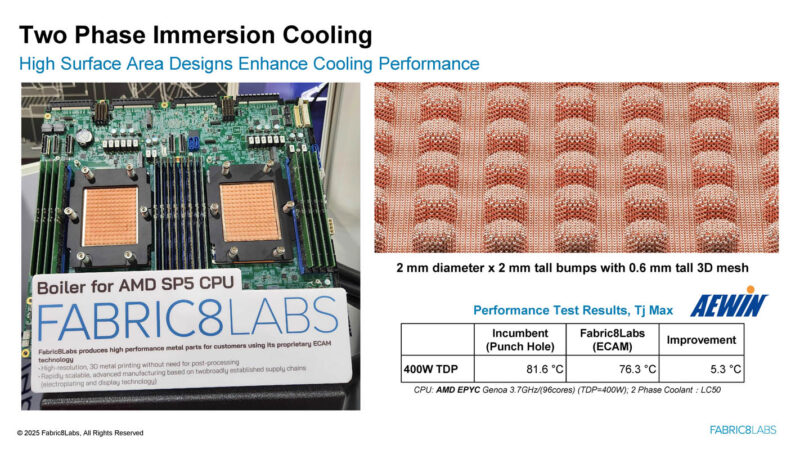

How cool is this? This is a 2-phase immersion boiling plate for immersion cooling. The idea here is to increase the surface area and optimize boiling of the fluid.

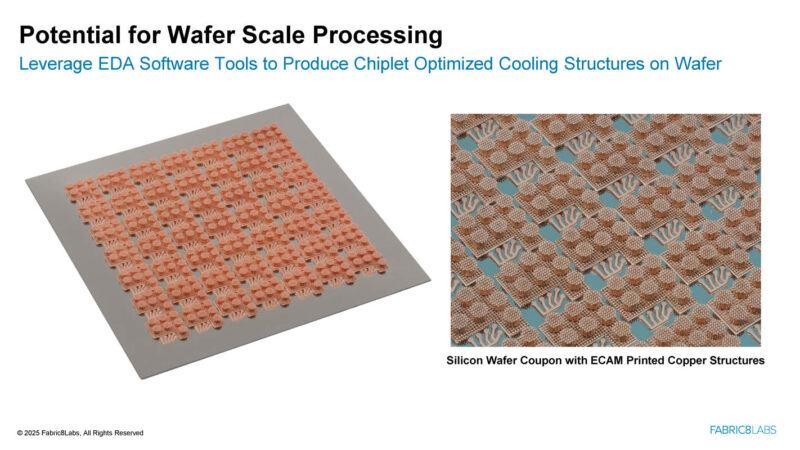

Eventually, EDA software in the future might design optimized cooling solutions for chiplets and systems.

In the future, we can see package level coldplats and the direct to silicon. That is what it sounds like. Printing the liquid cooling thermal solution directly onto the silicon.

Here is the company’s overview slide.

Final Words

There are few presentations from companies where things just make sense. I actually think server manufacturers should use this technology to differentiate offerings. For example, you can buy standard coldplates, or get custom made coldplates as an up-sell. That would help with providing differentiation to customers. Also, when you think about how costly modern accelerators are, the cooling solutions are relatively low-cost items that are also ripe for optimization.